Gold applications in PCBs

27 October 2023

Views: 585

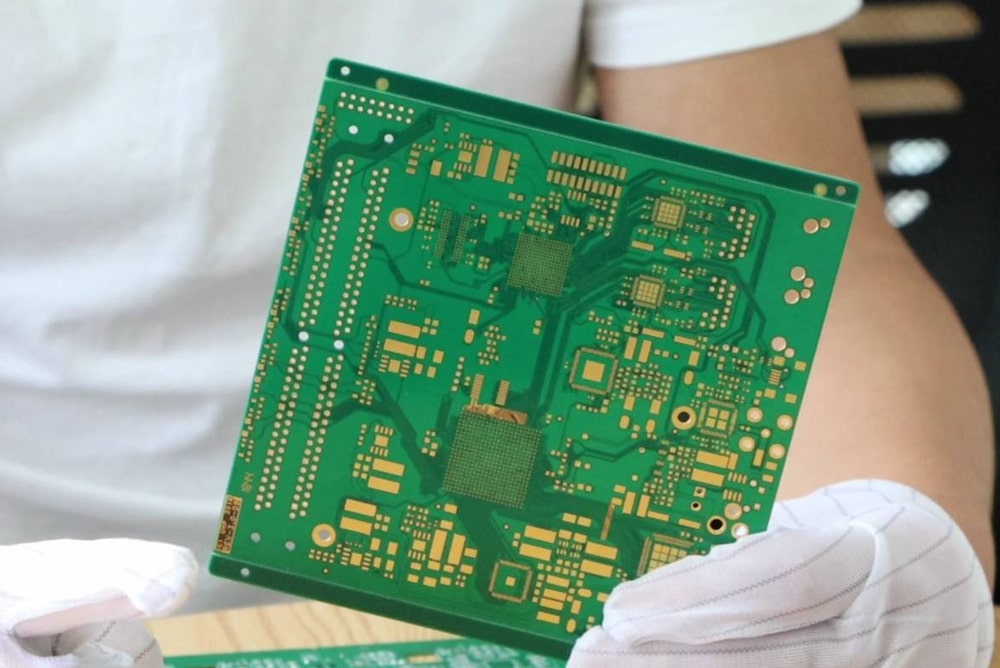

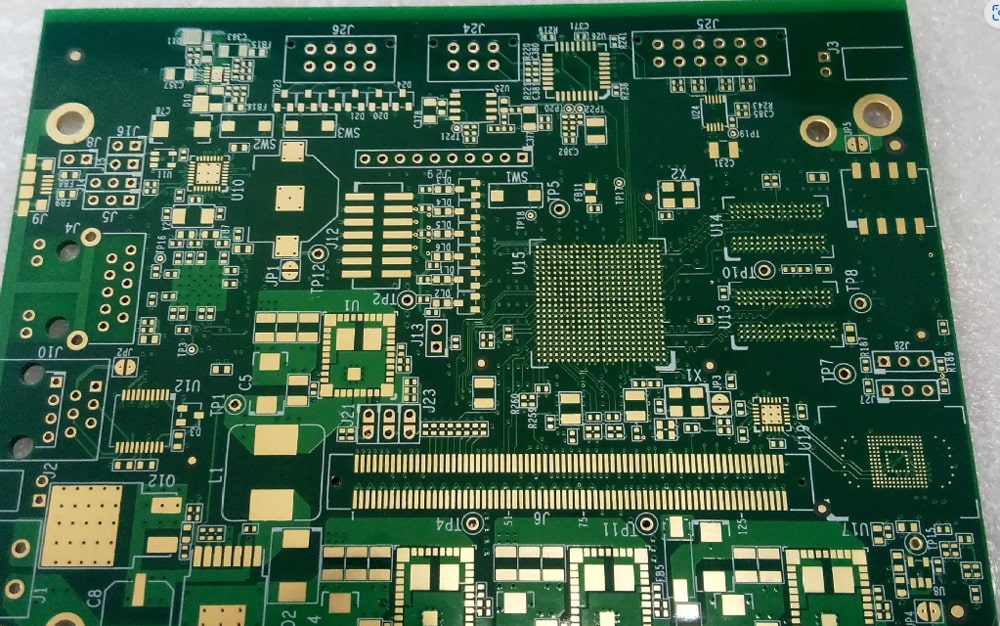

Gold applications in PCBs Gold is a valuable metal with a wide range of applications, including in the manufacture of printed circuit boards (PCBs). Gold is used in PCBs for a number of reasons, including its high conductivity, resistance to corrosion, and ease of soldering.

Gold is a good conductor of electricity, which makes it ideal for use in PCBs. The conductivity of gold is about 70% higher than that of copper, which is the most commonly used metal in PCBs. This means that gold can help to improve the performance of PCBs by reducing the amount of resistance in the circuit. Gold is also resistant to corrosion, which makes it a good choice for use in PCBs that are exposed to harsh environments. Corrosion can cause PCBs to malfunction or fail, so it is important to use materials that are resistant to this type of damage.

Gold is also easy to solder, which makes it a convenient material for use in PCBs. Soldering is the process of joining two metal surfaces together using a molten metal alloy. Gold is a good choice for soldering because it has a high melting point and does not react with other metals. In addition to these benefits, gold also has a number of other advantages, including its aesthetic appeal and its durability.

Gold is a beautiful metal that can add a touch of luxury to any product. It is also a durable metal that can withstand wear and tear. For these reasons, gold is a popular choice for use in PCBs. Gold is a valuable metal with a number of properties that make it ideal for use in this application.

What is gold plating?

Gold plating is a process by which a thin layer of gold is deposited on a metal surface. This process is often used to improve the appearance of a metal surface or to protect it from corrosion. Gold plating is also used in the manufacture of PCBs.

Why is gold plating used in PCBs?

Gold plating is used in PCBs for a number of reasons, including:

To improve the electrical conductivity of the PCB.

To protect the PCB from corrosion.

To make the PCB more aesthetically pleasing.

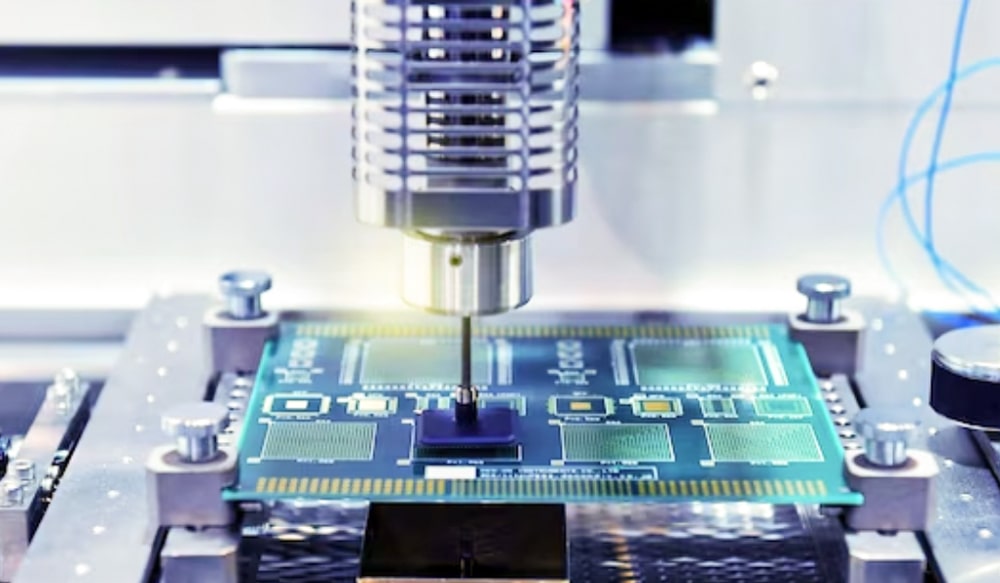

How is gold plating done?

Gold plating is done by a process called electroplating. In electroplating, a metal object is placed in a solution of gold ions and an electric current is applied. The gold ions are attracted to the metal object and deposited on its surface.

What are the advantages of gold plating in PCBs?

The advantages of gold plating in PCBs include:

Improved electrical conductivity.

Increased corrosion resistance.

Improved aesthetics.

What are the disadvantages of gold plating in PCBs?

The disadvantages of gold plating in PCBs include:

The cost of gold plating.

The complexity of the process.

The environmental impact of gold mining.

Conclusion

Gold plating is a valuable process that can be used to improve the performance and appearance of PCBs. However, the cost and complexity of the process must be considered before deciding whether or not to use gold plating.