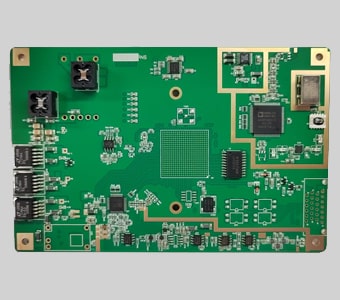

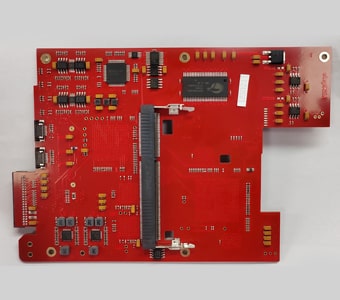

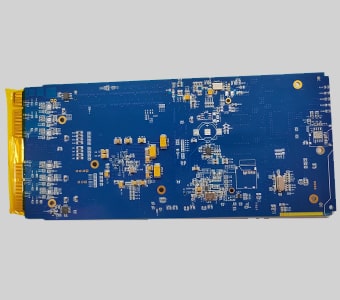

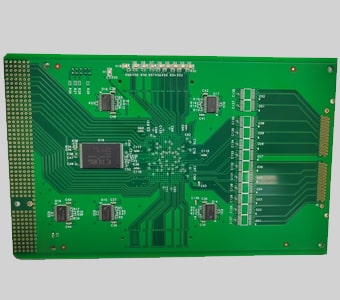

Established in 1996, POE is a leading manufacturer of PCB and PCBA. With its own production facility in China, spanning over 40,000 square meters of PCB manufacturing capacity, POE delivers high-quality PCB and PCBA services to its customers.

- ☞ 400+ Professional Engineers

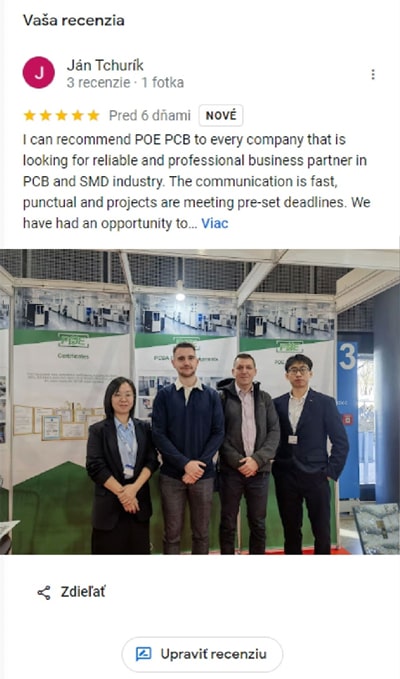

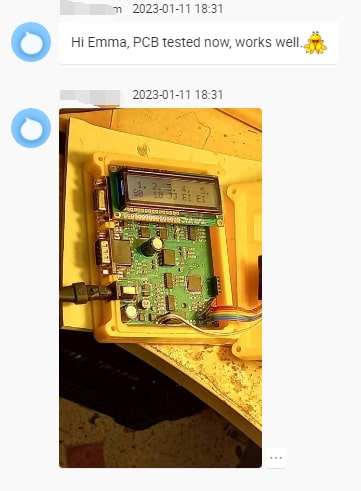

- ☞ 99% Customer satisfaction

- ☞ 200+ Cover Countries

- ☞ 4000+ Customers