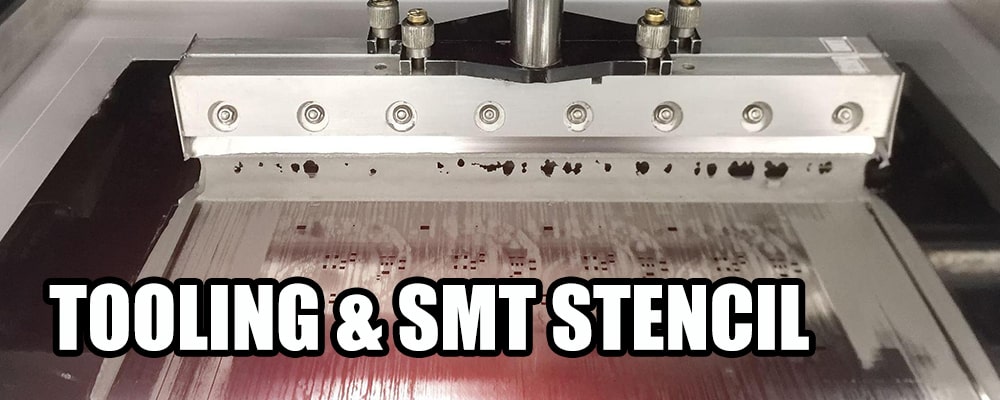

POE PCB Stencil Service

There are 4 points to be notified about POE stencil making:

Specifications: Commonly used size are 37*47cm, 42*52cm, 52*52cm, 55*65cm, and different specifications of SMT stencil can be customized according to customer requirements.

Mark point location:There are two kinds of marks on stencil for your SMT machine placement: Through hole MARK points and half-mark MARK points. Usually we use the technology of half mark.

Polishing process:Grinding polishing, etched polishing, electrolytic polishing are the 3 main processes. Usually we use grinding polishing, etched polishing and electrolytic polishing need to be charged extra. For PCB boards with IC pin spacing equal to or less than0.5MM or with BGA package, etching polishing process or electrolytic polishing is recommended.

Function of SMT stencil:Solder paste net and red glue nets recommended.

Aspects influence the quality of the stencil

1.Treatment Technologyetching polishing process or electrolytic polishing is much more flat.

2. MaterialIncluding frame, wire mesh, steel sheet, adhesive and so on. The screen frame must be able to withstand a certain program of relay and have a good level; the wire mesh is best to use polyester mesh, which can keep the tension stable for a long time; the best steel sheet is No.304, and the matt one is better than the mirror one;

3. Pads Opening on PCB design file;

4.The way to use it;

5.Cleanness6.Storage.

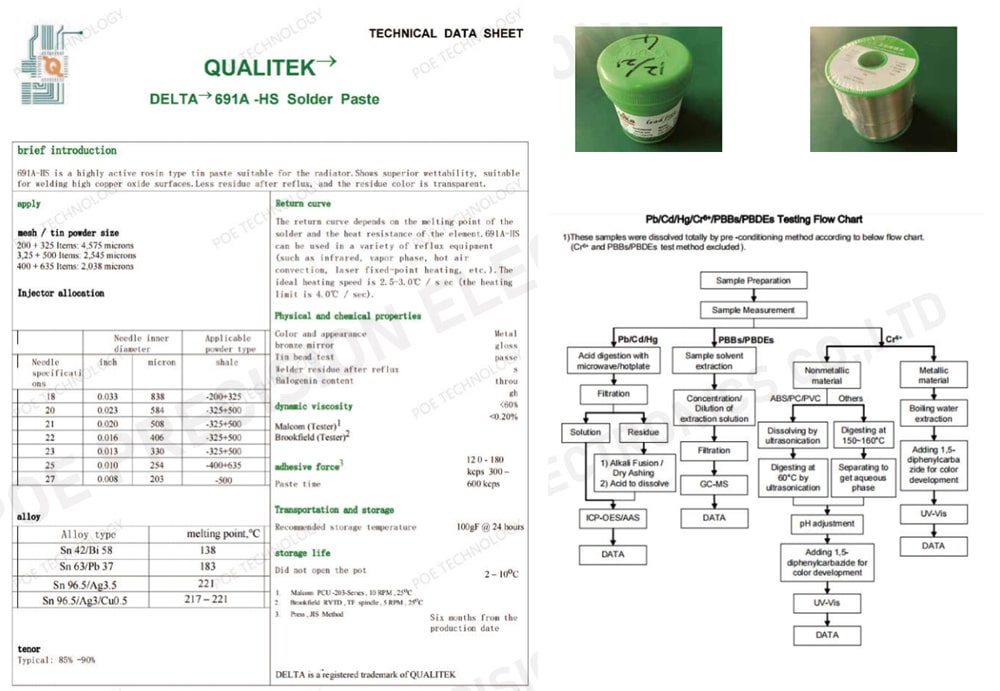

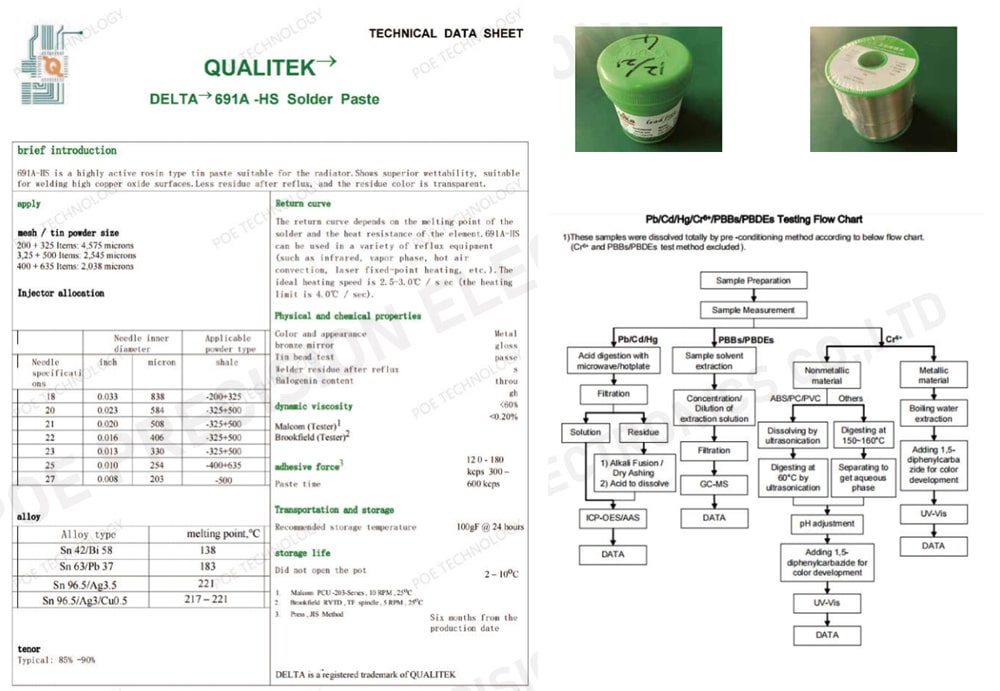

Solder Wire and Paste Materials

POE use DELTA 691A-HS Solder Paste for SMT and DIP production which is a world famous brand.Different quality of solder paste result in different assembly quality: 691A-HS is a high active rosin type solder paste for heat sinks.Demonstrates superior wet ability and is suitable for soldering high oxide copper surfaces. After reflow, there is little residue and the residue color is transparent. This is also ROHS and ISO9001: 2015 certified Here on the left is the datasheet:

Email: all@poe-pcba.com